In the current wave of intelligent manufacturing sweeping through all links of industrial production, the demand for automation upgrading in- the stamping industry is particularly urgent. As an innovative pioneer in the industry, Jehson, based on the group standard Swing Arm Stamping Loading and Unloading Robot T/FSAS 15—2018 that it led in drafting, has launched the swing arm stamping loading and unloading robot, which is becoming an important tool to break through traditional production models and enhance the competitiveness of the stamping industry.

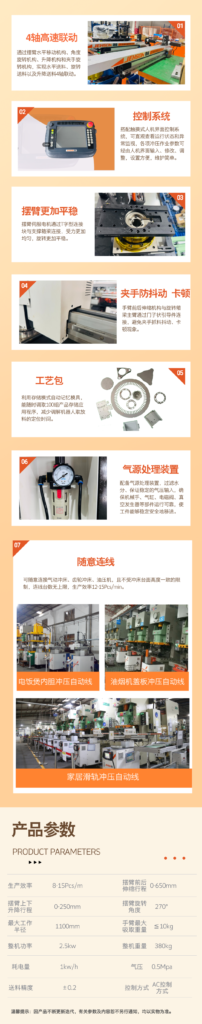

This product is equipped with an a self-developed high-performance motion control system. Utilizing four-axis precise linkage technology to achieve efficient coordination of the arm’s vertical lifting, horizontal extension, lateral swinging, and 270° rotation of the suction cup, It maintains positioning accuracy within ±0.2mm. While ensuring high-speed operation, it ensures stability in complex working conditions, providing a reliable support for precision stamping operations.

This equipment has been widely used in home appliance manufacturing, automotive parts processing, hardware product production and other fields, effectively solving the efficiency bottlenecks and safety hazards of manual operations. In practical applications, the equipment can be adapted to stamping equipment of different tonnages, helping customers achieve a double improvement in production efficiency and yield rate.