Recently, 50 students from Leliu High School visited Kaishuo Technology, embarking on a unique journey to explore intelligent manufacturing. From hardware molds to industrial robots, the students experienced firsthand the technological marvels of modern manufacturing.

Entering the Workshop: From Mold Processing to Robotics and Automation Equipment Manufacturing

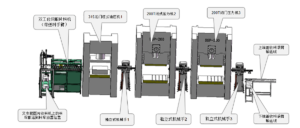

In the mold workshop, the students witnessed a metal “metamorphosis”: an ordinary piece of metal material, meticulously shaped by precision machining equipment, transformed into high-precision molds. These molds are widely used in industries such as household appliances, automotive parts, hardware, and electronics. The clean, orderly workshop environment and standardized production processes gave the students a clear understanding of the “craftsmanship spirit” in modern mold manufacturing.

In the automated assembly workshop, the flexibly moving stamping robotic arms became the center of attention. These “iron craftsmen” not only perform high-precision tasks but also replace humans in hazardous operations. One student joked, “It seems if we don’ t study hard, even ‘tightening screws’ will be taken over by robots!” Behind this joke was the students’genuine impression of intelligent manufacturing.

Dialogue Between School and Enterprise: Discussing Talent Development in Intelligent Manufacturing

During the post-tour symposium, corporate executives engaged in in-depth discussions with teachers and students. Xie Chuan He, Deputy General Manager of Kaishuo Technology, stated, “The era of intelligent manufacturing demands versatile talents who understand both technology and innovation.” Li Wen Hu, Marketing Director, used clay modeling to explain the working principles of stamping molds. Through vivid examples of mold applications and automated production cases, he demonstrated how intelligent equipment is transforming traditional manufacturing. Yang Mei, Director of Human Resources and Administration, shared her career growth journey, emphasizing the importance of continuous learning and building a three-dimensional growth system by deepening professional skills, expanding cross-disciplinary knowledge, and dynamically adjusting learning directions.

Significance of the Event: Building an Educational Loop and Deepening Industry-Education Integration

“This study tour showed us the application of textbook knowledge in real-world production, far exceeding our expectations,” commented the lead teacher. She noted that every segment, from the manufacturing of precision molds to the precise control of industrial robotic arms and the career insights shared by executives, served as a vivid vocational enlightenment lesson. The event is also expected to inspire students in their studies and future career development.