In automotive manufacturing, over 95% of components rely on molds for shaping. Molds are integral throughout a product’s entire lifecycle, present everywhere from body panels to precision electronic components. As the “mother of industrial manufacturing” for automobiles, they serve as a core pillar for automakers to reduce costs, improve quality, and respond swiftly to market demands.

The Craftsmanship of Different Types of Molds

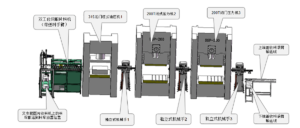

In the automotive sector, stamping molds are critical core equipment. Stamped parts account for about 40% of a vehicle’s components, typically requiring over 1,500 sets of stamping molds. With exceptional manufacturing capabilities, these molds shape the smooth contours and sturdy frames of body panels. From engine hoods to sharply angled rear fenders, every precise curve showcases the artistry and technical prowess of mold craftsmanship.

As a leader in stamping molds, Kaishuo Technology adheres to innovation-driven and precision craftsmanship principles, offering global automakers end-to-end mold solutions from design and development to mass production. The company gathers top-tier technical talent, leveraging advanced design concepts and cutting-edge manufacturing techniques to ensure each mold is a perfect fusion of art and technology.

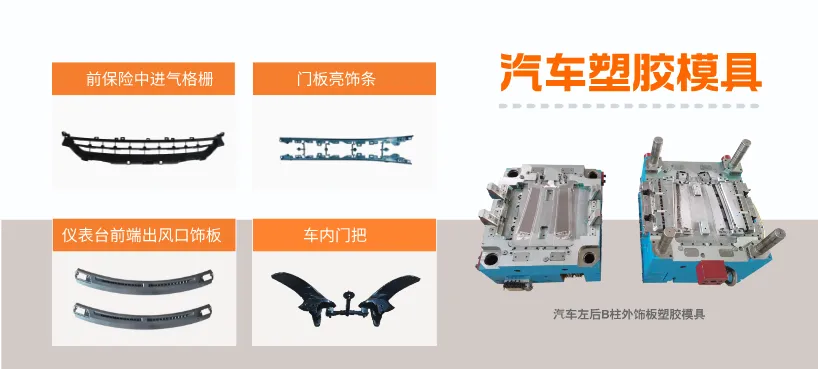

With the advent of electric vehicles, autonomous driving, and the new energy era, lightweight automotive design has become inevitable. Plastics play a pivotal role in this trend, making plastic molds particularly important. As the key enabler of automotive interior upgrades, plastic molds transform design concepts into exceptional products. From soft-touch dashboards to ergonomic seat shells and acoustically optimized door panels, advanced plastic molds combine functional needs with human-centric design through precision molding, creating comfortable, intelligent, and tech-savvy immersive experiences for drivers and passengers.

Xinshuo, a subsidiary of Kaishuo Technology, has been specializing in automotive plastic molds. With a team of 40 experienced mold engineers, the company anticipates potential issues in molding, ensuring product quality stability. Its intelligent production system offers integrated services from design and mold manufacturing to product delivery, making it a trusted partner for many automakers.

High Precision and Reliability of Mold Craftsmanship

From small components like lamp housings and air conditioning ducts to large parts like frames and wheel hubs, molds are ubiquitous in automotive manufacturing. With micron-level precision and millions of repetitions, they ensure every part meets stringent standards, turning design blueprints into road-ready vehicles. This relentless pursuit of precision and reliability embodies the “artisan spirit” of the mold manufacturing industry.